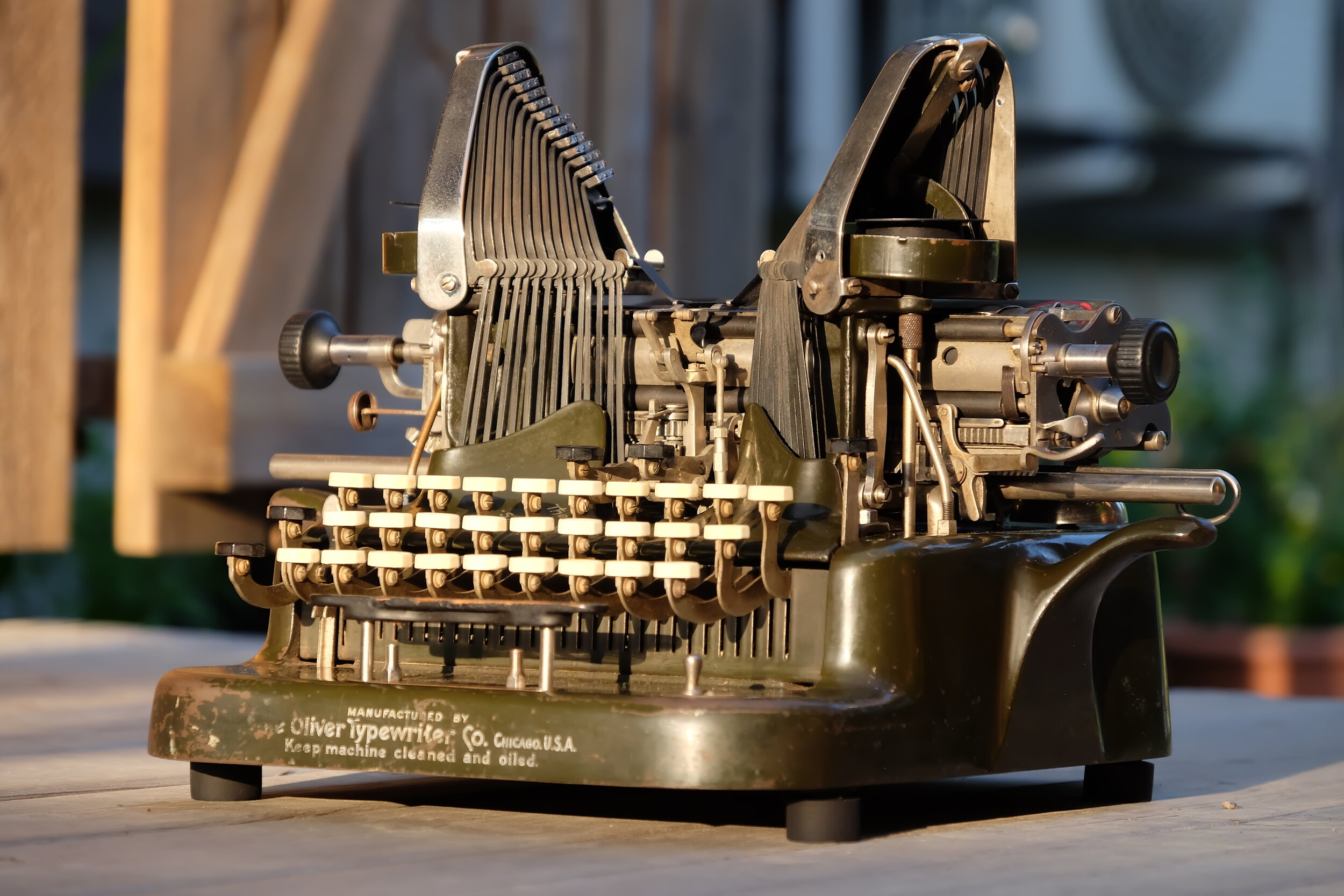

Antares Parva

Italians have a sense of humour giving such a name.

Antares (anti-Ares in Greek mythology), know also as anti-Mars or Scorpions'-Heart is a gigantic M1 red supergiant in Scorpion constellation, close to end of its life.

Parva, on the other side, means little in Latin (as opposed to magna).

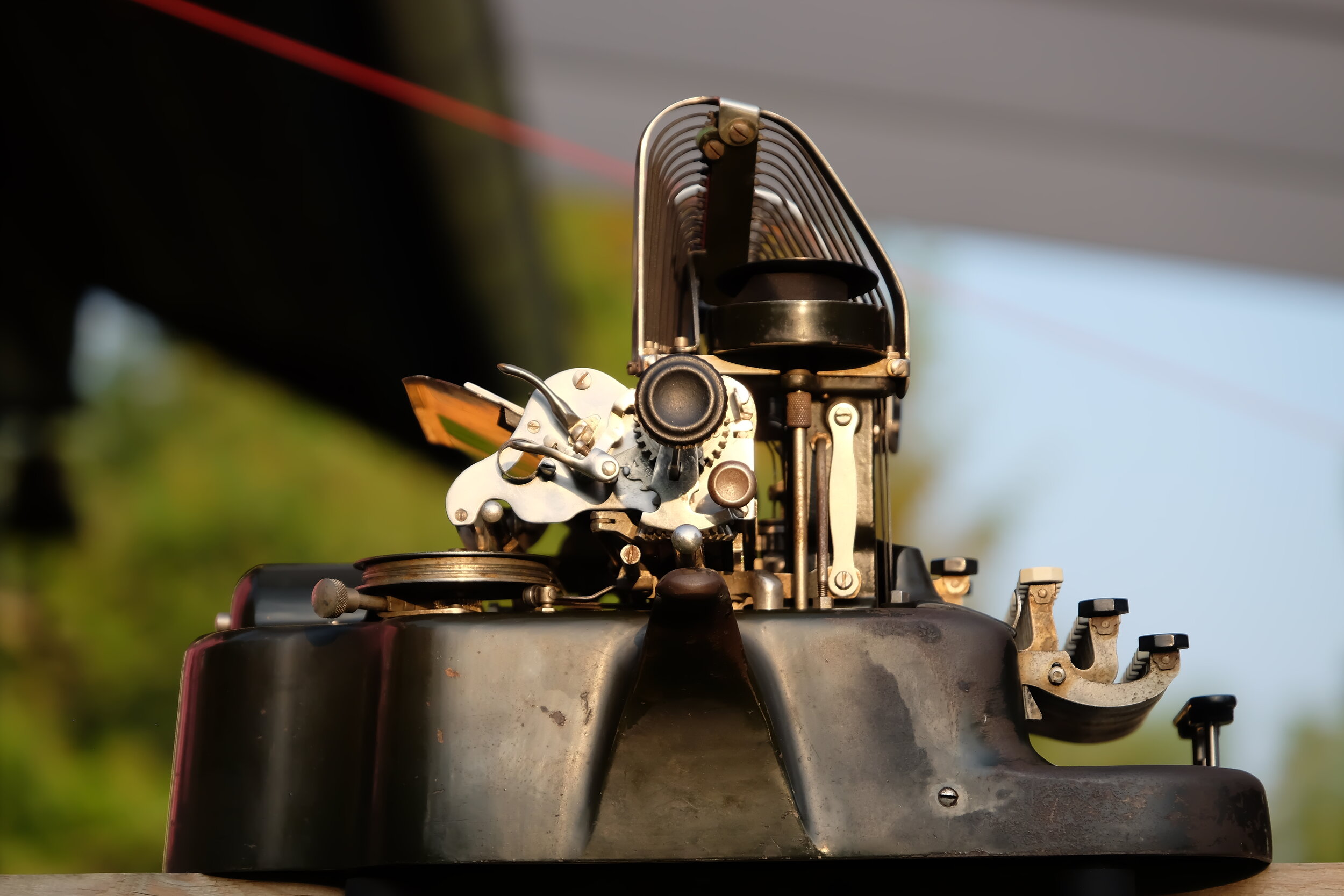

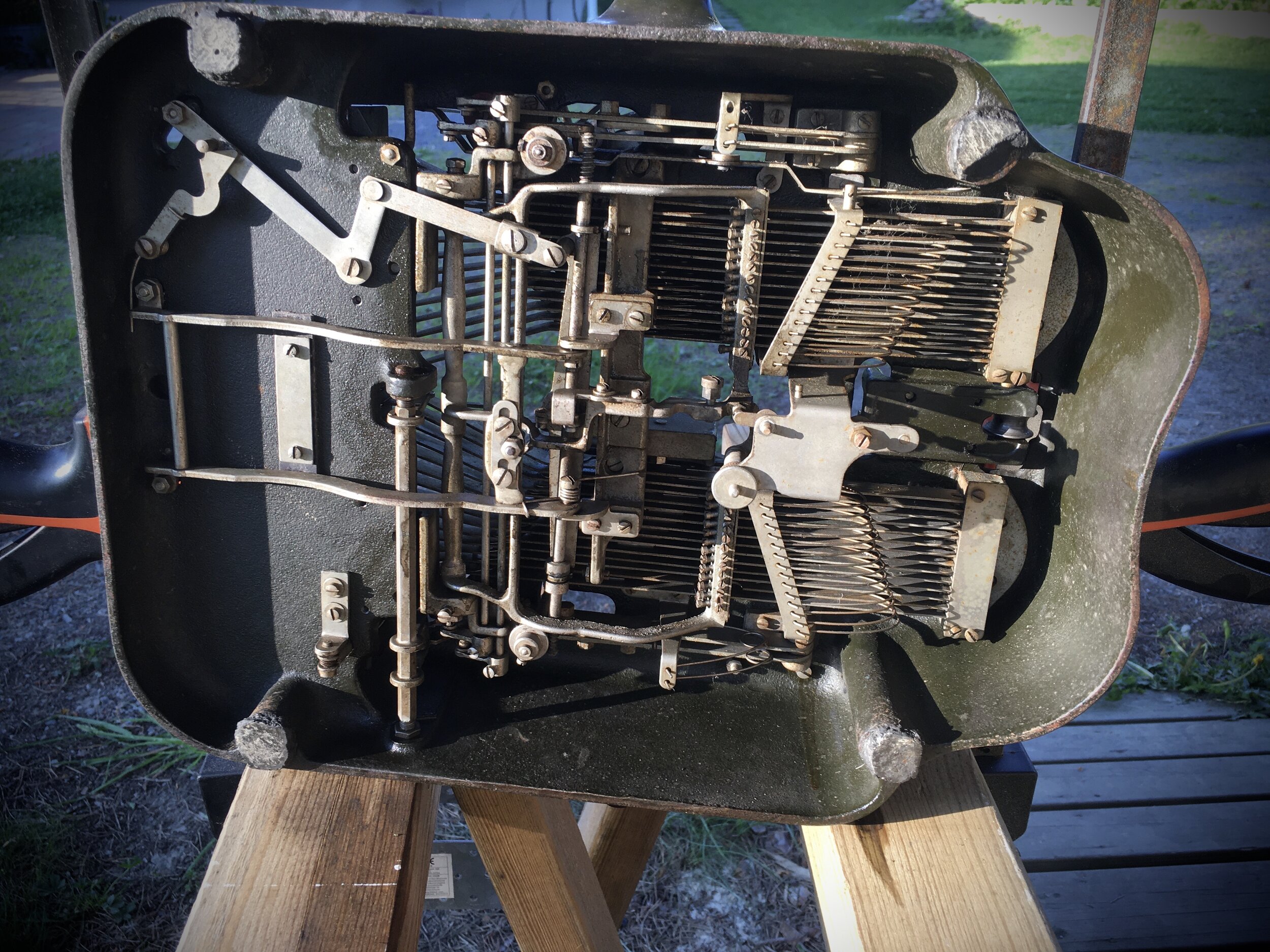

So there we have it: skinny ultraportable typewriter, relatively unknown in Typosphere. Given it’s resemblance to Hermes Rocket/Baby which I have I was not sure if I want to get yet another one. But the price was a real bargain so I bit the bullet and got it.

Oh dear, and I’m not disappointed! Oh no, indeed.

More about the machine can be found here.