Remington Rand 5 with rotten keys. Fallout machine.

This was one of my “parts machine”. It had ugly, damaged and rusted keys and lacked parts which I picked for fixing other machine. Body panels, originally in crinkled black, were ugly repainted at some point. I planned to dismantle the machine into screws and spare parts and throw the rest.

But there was some life in her and, more importantly, typeface is in Elite-size. I decided to give her a chance.

First I needed to remove the paint. That went quickly, with heavy chemistry and a few days of soaking in plastic bags.

I like this bare-metal look. Streamlined body looks nice in silver, a bit like Airstream.

Keys then.

There were no signs of corrosion in the whole machine apart from keys. Key legends were delaminated and sticking out of key rings. I suspect that someone cleaned the machine with water at some point. It got soaked into cardboard key-legends and stayed there for years, doing its nasty job.

I don’t have a dedicated tool for removing key rings so I made my own: converted nail lifter (ugh!). It is a bit finicky to use but it did the job alright and costed me 10 dollars plus some effort to re-work it.

With key-legends removed the scale of damage could be assessed.

Definitely job for Evaporust. At first I dispensed it only into key cups, hoping that a few hours soaking will dissolve the rust.

It didn’t so I doped the whole keyboard and left it for a few days.

That did the trick: keys emerged with no trace of rust.

I punched new legends from synthetic cork. It is water resistant and offers a bit of cushioning for fingers.

My plan was to cover the cork with printed key legends in classic style: black letters on white paper. However - why not leave the cork visible? Will it not add a bit of organic warmth to this otherwise cold-steel machine?

I took her out into sunlight to decide.

Ain’t bad, no? A bit MadMax style. Or Fallout maybe?

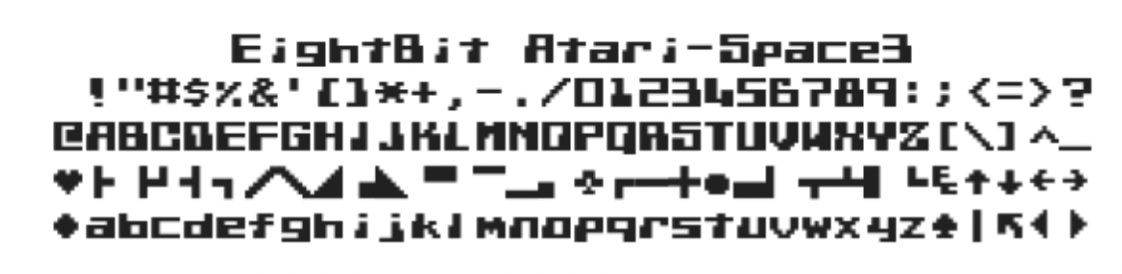

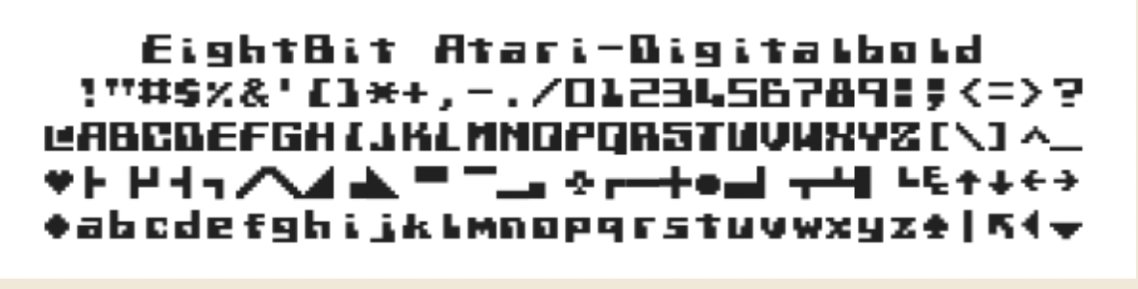

OK, so let’s make key legends in a bit unusual typeface, to go with this sci-fi theme.

I printed them, in mirrored direction, on OHP-foil. This way the plastic is protecting printed letters from being wiped during typing.

Key rings, cleaned and polished, were easy to press back into their place. I used a set of parallel pliers and thin wooden stick to protect the rings.

And so it became quite a sexy machine! I made new springs in place of these which were missing, fixed problems with the mechanics, cleaned and oiled the mechanism and she types again.

It looks that we have a survivor!