Blickensderfer No.8. German Blick.

So far this is my first Blick.

I am fascinated by this design so I got this machine from Germany. Upon arrival it was totally non-functioning, mostly due to dirt and dried oil covering the internals.

By carefully exercising the mechanism, in conjunction to figuring out what all these levers should do, I got the machine to move. Reluctantly and with reservations it came back to life.

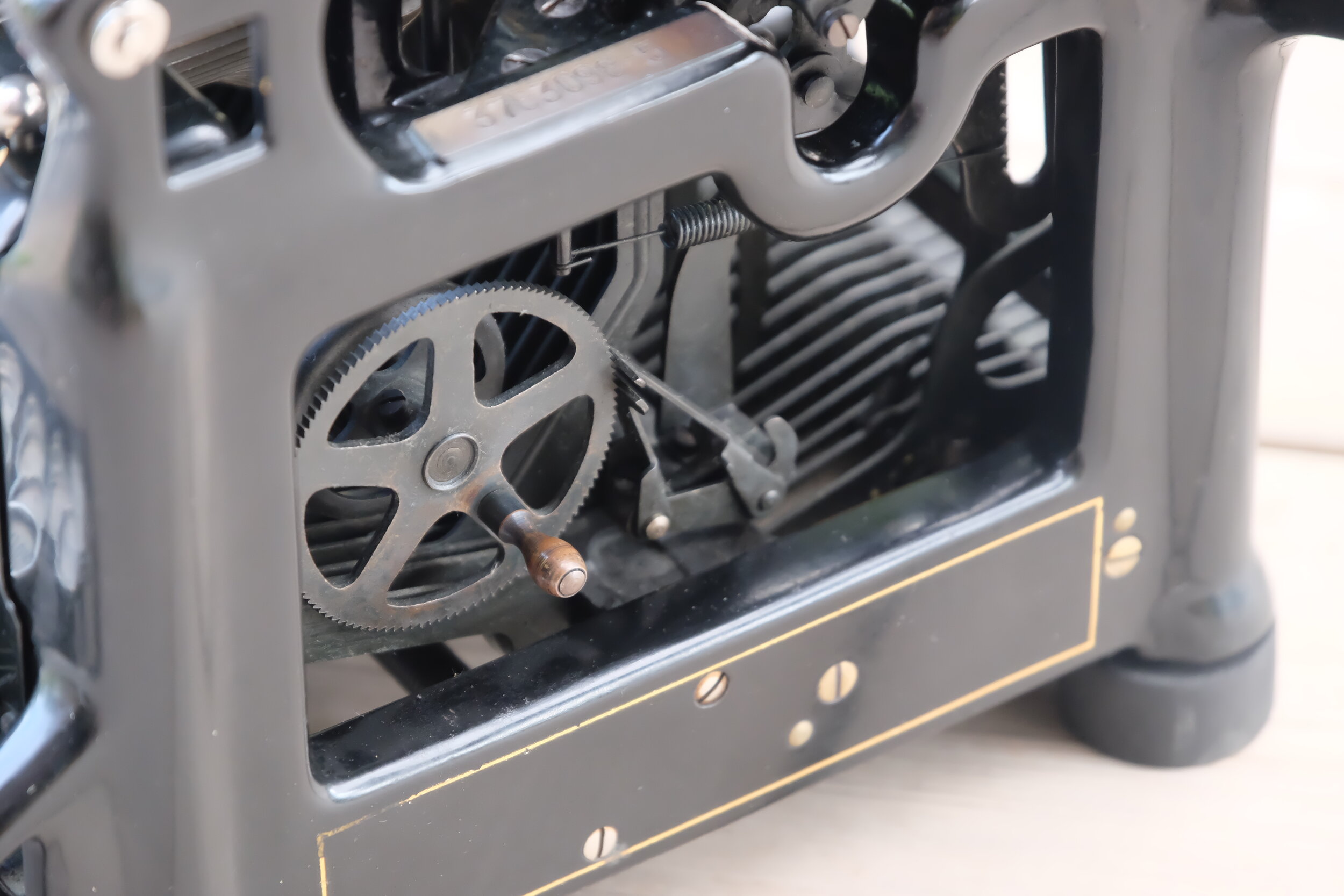

Thanks to (limited) YouTube clips and Typosphere I figured how to remove the carriage - very easily indeed, almost like on Olivers but to the right. My biggest surprise was that there is no drawband nor spring-motor in this machine. Instead Blick is using push-pull escapement. So no broken pull string nor broken engine spring - so common on Olivers.

After blowing some of the dust bunnies I reached under the machine to start taking it into parts.

Some missing springs, a few was found inside the carrying case laying loose below the machine.

Dirty but luckily with no surface rust. I remove them one by one.

Removing the type wheel was scary as it is hollow and entirely made of hard, vulcanised rubber. Being more than 100 years old it was sitting hard on its axle. With some isopropanol I got it loose eventually and managed to remove it without the damage.

There are two types of springs under the key levers. Those with short loop at the end are hooked onto the universal bar. Only handful of them, the rest - with straight end - are for each key lever.

I continue with removing the main push-bar. It is enough to remove one screw to tilt the side arm, the whole subassembly can be then slid out of the frame.

Now I gain access to the remaining springs.

By loosening three screws one can remove the plate holding key levers in place.

Here is the picture of the keyboard just before I start removing each key. Now I know that, apart from this I should have numbered the keys in the order I removed them. It would simplify re-assembly procedure as this single photo does not clearly say in which order they sit in their guiding combs - many levers are bent so as they pass over their neighbours but top-side view has this often obstructed.

Removing key-levers is easy: unhooking them from their respective, short bars and lifting out of the mechanism. A few dead spiders were found in the process.

To me one of the crucial parts of any typewriter: a bell. Here the bell sits on its own arm. I remove the subassembly for cleaning.

Left margin rail follows.

Almost there. I gained good enough access to internals for cleaning.

Should I stop here?

This front comb is chrome plated. I want to polish it properly. I move on with further dissection.

Back of the machine, under the carriage. Escapement is now fully accessible.

While figuring out how to proceed further I remove key tops for proper cleaning. Key legends are made of thick cardboard, sitting tightly in key cups, with convenient side-slots for lifting cardboard rings. Springy key rings are safe to remove, unlike more common design with soft, folded tabs which can easily brake.

Back to the front comb: I remove Figure and Shift lever.

Cast-iron keyboard frame comes next…

… but the locking lever - spring-loaded - must come out first.

The machine looks now like it’s older brother Blick No.5, skeleton-typewriter.

Before the comb can be removed I need to unscrew Shift bottom screws. They determine how high the print roller moves so I measure their height before moving locking nuts.

Finally both combs can be removed.

A bit of wiggling and flexing was needed to get this guy out.

There I reached the mental stop: to remove last key levers I would need to unscrew them but that would require disassembling the heart of the Blick - and I was wisely advised not to do it, only if absolutely necessary.

Until I get another Blick - to have a reference in case I mess up synchronisation of the mechanism - I keep my hands away from Blicks’ heart. These remaining three keys will be cleaned in situ.

Bare bone machine (almost) ready for next step.

Key-base turned out to be brass - I clean them from dirt. Oxidation - by some referred as patina - will be back very soon so I don’t sweat over it.

Brushing with my mixture of white spirit & some engine oil.

Rubber feet are in acceptable shape after external layer of oxidised rubber is removed.

They are, however, not grippy enough and moreover they are too small to keep the machine from moving inside wooden case cavities. I decided to make new feet from fresh rubber compound, wider in diameter to mach the case.

There! Cleaned frame and remaining part of the mechanism which I didn’t dare to remove. I put back keyboard frame and space bar.

Moved to most tedious part: cleaning and polishing each key and keylever. That took me a while.

Key-top rings were originally coated black but on many keys the paint deteriorated and steel got rusty. To repaint them I needed first to clean the old, damaged coat and remove rust. After seeing the effect of cleaning I decided to leave them with white, bare metal tops for now. The machine will get some brighter accent with shiny keys. Jeweller-maker’s clamp helped a lot with holding these small rings when polishing.

Then came the time for springs - thin and tiny. I cleaned each one with soft abrasive pad.

After putting back all the keys I finally install their respective springs. Shiny and clean they please the eye, even though they live on the bottom of the Blick, not visible normally.

It turned out that only one spring is missing. I make a copy from thin-gauge piano wire.

The rest of removed parts got cleaned and polished, frame waxed with Fulgentine. Nice and shiny! I oil all parts which move under load leaving everything else oil-free.

Time for a carriage!

Unlike minimalistic Blickensderfer 5 this Blick 8 is a luxury machine - it even has carriage return lever integrated with line advance mechanism! I remove it as first, noting weak spring for keeping it in upright position.

Springy rod which decouples escapement and enables shifting the carriage is removed next. It holds in place small paper table which now can be removed, too.

To unscrew the line spacing wheel - almost like a knurled screw - I had to soak it for a few hours in penetrating oil. Meanwhile I continued dissection of the surrounding mechanism.

Unhooking springs is risky here as their ends are bent around their fittings. I decided to keep them hooked to avoid the risk of braking them.

Line advance wheel finally gave in!

Diving deeper into this side of the carriage.

Carriage release lever sits on a small collar washer. Good to not loose it in the process.

Blick is a fascinating machine also with regard how many adjustements are available to the user. Not only line spacing can be adjusted to whatever distance - unlike on other machines where only “clicked”, predefine spacing is available - here one can decide how early the ring will rang (black screw) before end-of-the-line blockade engages (spring-loaded tongue above) and stops the carriage from moving!

Front ruller is spring loaded on both sides, keeping the page pressed towards the platen. Off goes even this!

And so I ended up with bare, cast-iron frame, all accessible for cleaning.

Lastly I unscrew both holding brackets for polishing.

I always have doubts at this stage if I will manage to put all these parts back together…

After cleaning and chrome polishing, ready for assembly. The platen is in good shape, I only sanded it to remove oxidised layer of rubber. It is still rubbery after all these years!

Putting it all back was surprisingly easy. The last part is the type wheel. I clean it in isopropanol.

Quite a bit of old ink went off.

I fabricate a new ink roller by punching it from natural felt. I want to experiment with different types of ink, keeping the original roller reserved for black ink.

Oak-case got repaired, lightly sanded and varnished.

I used traditional varnish (Epifanes) as it was certainly what was used originally. The case is curing in the evening sun.

That concluded the restoration.

Ready for typing!

Bell-lever spring (for Ricardo)

On my machine the bell-lever is actuated by torsion-spring which is installed on lever´s pivot axle:

Spring´s one arm is extending through screw-head and is barely visible where the arrow points below:

Now when I look closely I see that there are two opposite holes which could indeed accommodate a small, “flatish” spring which could do the same:

I imagine on Bruno´s machine it is like that but the spring is too tall and is in a way of moving carriage.