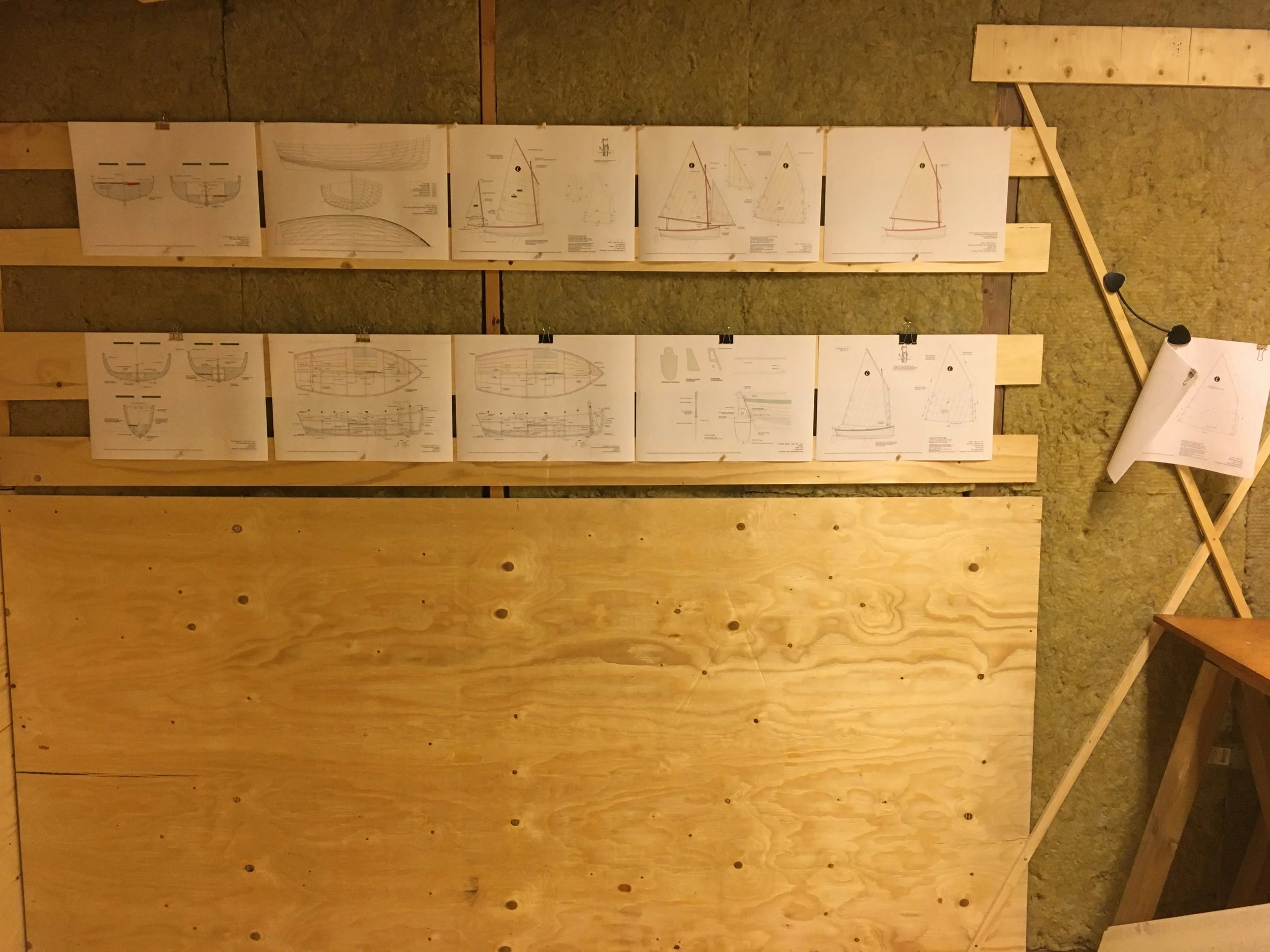

And here they are!

While waiting for delivery I was sourcing wood for floor boards, keel and keelson. Plans specifiy which wood is suitable for which part. In case of keel and keelson it may be, among others, mahogany or spruce. Oak was not specified due to difficulty in epoxy bonding but I was leaning at first towards it.

I have glued successfully oak before, while repairing frames and engine beds on Meritaten. I use WEST Flex epoxy, formulated for exactly this purpose.

I checked with the designer, Francois Vivier, that it would be OK to use oak if I am confident that I can glue it well.

My reasoning was that I will need anyway a bit of balast on this boat, as I will mostly sail alone. Having a bit more weight down below, in form of denser and heavier wood will help.

After giving it some more thought I decided not to diverge from the plans. Oak will move a lot once it gets wet and this boat will go through many wet-dry cycles during its life. My initial plan was to encapsulate it in epoxy, so that the wood will never get wet.

Yeah, in theory… It will, inevitably, get wet when I scratch or damage epoxy coating while dragging the boat onto beach or trailer.

During Xmas I had enough time to read Iain Oughtred’s Clinker Plywood Boatbuilding Manual and J.Brooks & R.A.Hill How to Build Glued-Lapstrake Wooden Boats. Both these books recommend other ways of protecting the wood than epoxy, discussing disadvantages of epoxy encapsulation.

They convinced me.

While encapsulating plywood has it’s place on board of the boat, in areas where plywood may get spray but is not constantly immersed in water (like cabin sole boards on Meritaten) it can cause more damage than good when water gets under the epoxy cover and becomes trapped there. With no way to escape the rotting process begins and does its job out of sight until the wood fails.

Yep, so I decided to stay with softwood, according to plans.

Sitka spruce is unavailable for me in this length here. I need strong yet easily glued wood with good rot resistance. I bought Siberian lark. I’m not entirely sure if I use it as keel but it certainly will be used for benches and sole boards.

I’m still considering getting mahogany for the keel. It will be expensive but… smakar det så kostar det.

Right now I cannot start gluing anything - it is still proper winter here, too cold for epoxy.

This weekend I will look closely onto the kit and start assembling the base for moulds. Before I put the moulds I’ll use the base as a bench, to cut scarves and glue planks.